Powering our partners

From world-first solar cell production to life-saving Defence machinery. Our projects showcase the depth of our capability.

Our projects

Operating at the forefront of design and manufacturing

Memjet D+M has a proven track record partnering with innovators, institutions and governments to unlock the potential of intellectual property. The commercial success of our projects across product design, manufacturing systems, R&D and data management speaks to the depth of our capabilities and commitment to our partners.

We take pride in positioning our partners at the forefront of their industries as we embark on the innovation journey together. We congratulate each of our partners on their advancements and are proud to showcase some of these initiatives.

Project types

Solar Skin:

Powering a Clean future

Solar Skin is a breakthrough technology with significant advantages over older solar technology and non-renewable energy. It has the potential to revolutionise solar power.

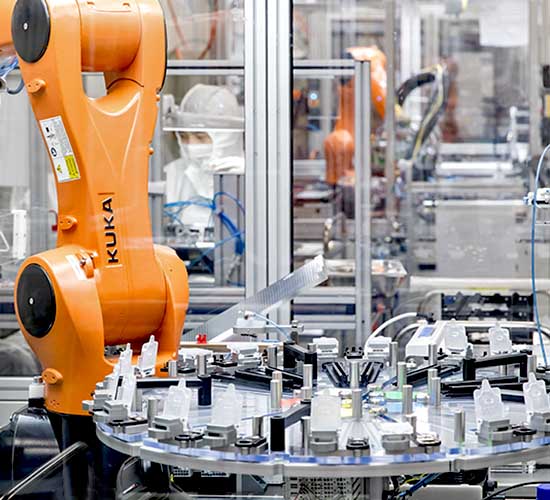

Memjet D+M has developed world-first manufacturing processes and bespoke equipment to help Solar Skin become the first provider of large and efficient perovskite solar cells produced at scale. This enables the commercial production of perovskite solar cells. Previously, manufacturing obstacles meant cells were produced in small sizes and non-commercial quantities.

What are Solar Skin perovskite cells?

Solar Skin’s perovskite cells are thin-film devices coated with layers of synthetic perovskite crystal solution. They convert light into electricity to produce a clean and renewable source of energy that has exciting potential and near endless applications. In the energy field, the term ‘pervoskite’ no longer refers to the mineral first discovered in the Ural mountains. Rather, it is a chemical structure that scientists can synthesise from common materials.

Why are perovskite solar cells difficult to fabricate?

Manufacturers globally have struggled to produce high quality, uniform perovskite cells in sufficiently large cell sizes and scales to be commercially viable. The precision required to produce delicate layers of crystals has been difficult to replicate a speed. As cell sizes increase, many manufacturers also find it difficult to maintain the energy efficiency of cells as compared to smaller cells. These obstacles pose a significant barrier to the wider adoption of solar skin cells.

How Memjet D+M has helped Solar Skin?

Memjet D+M has made unprecedented advancements in manufacturing perovskite cells to position Solar Skin as the global leader in perovskite cell production. We’ve applied our extensive expertise in fluid management and printing processes to develop a ground-breaking manufacturing system capable of producing 1,300 large perovskite cells per day. These cells maintain the energy efficiency previously associated with very small cell sizes.

The race for renewable energy

Solar Skin and Memjet D+M’s advances in solar cell manufacturing are the result of ultra-precise control over the crystal formation process and production environment. This finite level of precision maintains cell efficiency to produce large solar skins capable of leading the future of clean energy production.

TOXIC AIR SENSORs

PROTECTING AUSTRALIA’S DEFENCE FORCE

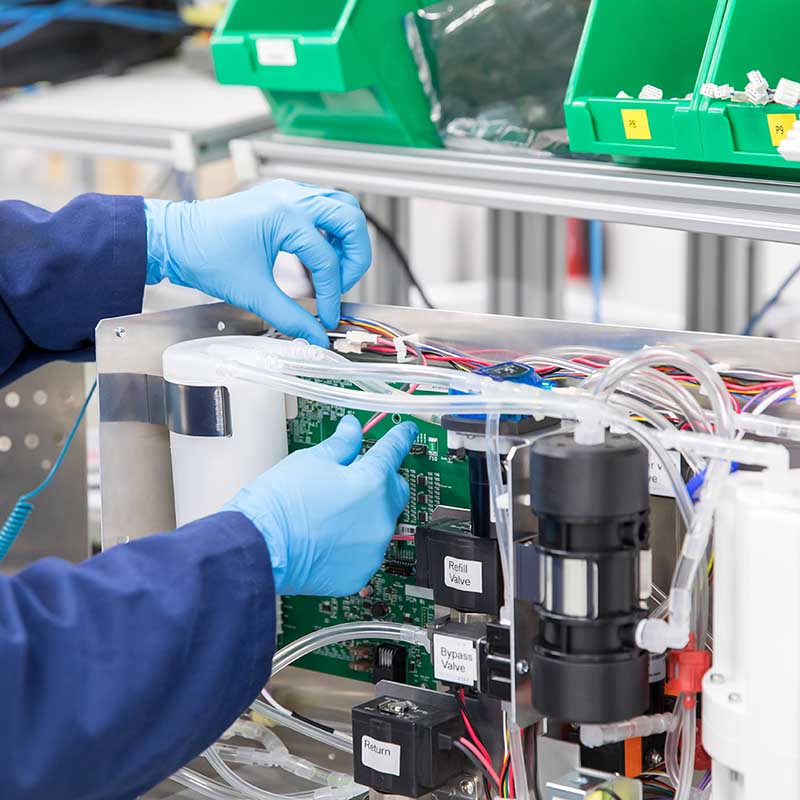

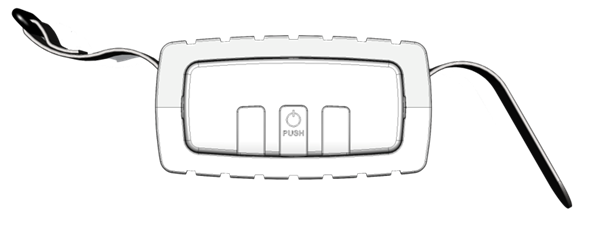

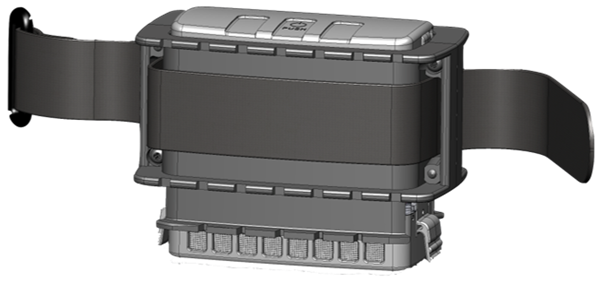

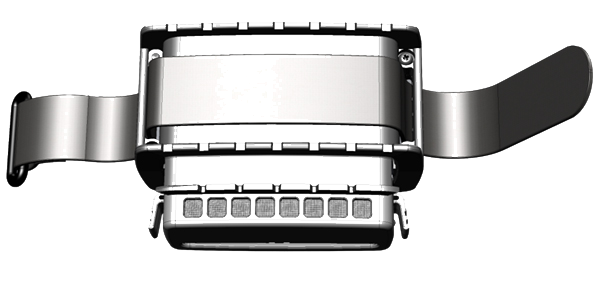

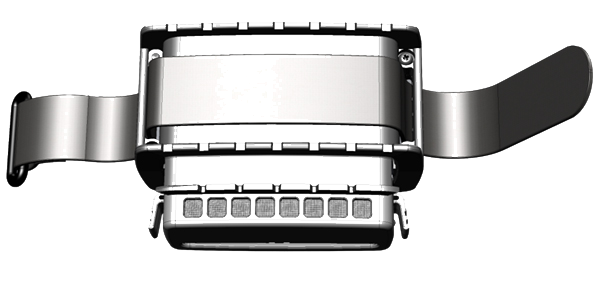

Toxic Air Sensor (TAS) is a wearable protective device that automatically detects air toxicity and contamination to alert users of potential hazards. It has highly advanced detection capabilities coupled with an automated build that simplifies operational use to the press of a button. Once the ‘on’ button is pressed, TAS sensors can automatically detect toxins in the air.

The device encompasses a sophisticated communications system with Bluetooth, wireless broadband, device discovery and data management capabilities. Including a battery life of up to 24 hours and ‘tool free’ infield replacement of consumable components, TAS is a live-saving device with extensive applications in military and industrial fields.

Protection against chemical weapons

Working in partnership with Flame Security International, Memjet D+M has designed TAS for use by the Australian Defence Force. This revolutionary technology can help protect Australian ground forces against chemical and biological warfare, enabling personnel to easily test their environments for airborne chemicals and toxins.

How it works

From an operational perspective, TAS turns on with the press of button. A simple push of the device opens the sensor chamber to airflow. Cutting-edge technology inside the air chamber tests for a range of targeted chemicals, sending real-time results to a paired mobile device, watch or phone, which alerts the user to hazards.

Technological advancements

Conventional methods for detecting and characterising air toxins involve isolating chemical particles on filters that are later analysed in a laboratory. TAS bypasses the need for laboratory testing using advanced cyclonic aerosol separation methods, aerodynamics and microelectronics to give real-time results. This sophisticated technology is easily operated, removing the need for extensive training or scientific expertise.

Supporting the DSTG

We are proud to work alongside the Australian Government’s Defence, Science and Technology Group (DSTG) to help improve the Australian Defence Forces capability to protect personnel from exposure to chemical, biological, radiological and nuclear (CBRN) weapons. TAS wearable devices may also help sustain military operations in CBRN environments, providing personnel with the intelligence necessary to avoid CBRN hazards.

CLADDING MONITORING SYSTEM

PROTECTING AGAINST HIGH-RISE FIRES

Cladding Monitoring System (CMS) is a real-time cladding monitoring system that monitors for fire on the external surfaces of buildings. The system provides complete surveillance of combustible cladding, removing blind spots and protecting occupants from fire.

CMS provides 24 by 7 monitoring to support a rapid response from fire emergency services, which have previously relied on emergency phone calls for information. With fast deployment and customisable solutions, CMS provides an affordable alternative to cladding replacement and a sense of security for building occupants.

Protecting against loss of life

CMS is the result of teamwork between Memjet D+M, Flame Security International and the University of New South Wales (UNSW). Our goal was to design an advanced and cost-effective solution to the global issue of high-rise cladding façade fires. Combustible cladding has caused a high number of fatalities and injuries globally, with the deadliest cladding façade fire at Grenfell Towers in the UK in 2017 causing 72 deaths and 70 injuries.

Audits of Australian high rises have identified thousands of buildings with combustable cladding in need of remediation. Strategies for remediation include the full or partial replacement of cladding (which is highly expensive) or the implementation of fire safety strategies.

How it works

CMS is a wireless fire safety device that attaches to building facades to provide external fire monitoring. This flame detection sensor is supported by back-end cloud infrastructure to enable real-time alerts and data management. The sensor integrates into existing fire control panels and delivers accurate data to first responders via a mobile app. The user-friendly app allows building managers to easily conduct diagnostic and system checks on all sensors.

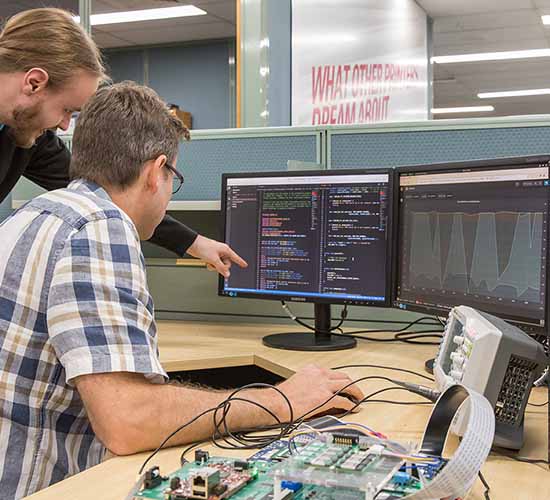

Expediated time-to-market

Our experienced team took CMS from a whiteboard concept to a scalable technology roll out in less than 12 months. We delivered an extremely fast time-to-market by using our end-to-end innovation funnel to reduce time and waste during the design and manufacturing process. This full-service process was aided by our automated production cells, which we configured to perform custom operations for the CMS project. Intensive in-house failure analysis then enabled us to test CMS against real world scenarios to ensure performance and durability.

Our Promise

Discover how Memjet D+M powers its partners with cutting-edge solutions.

Our Capabilities

Find out how our extensive capabilities can help you drive product innovation.

Our ingenuity

Learn about our innovative approach to modern manufacturing.

The Right support for Your ideas

Our commercial mindset supports innovation

Product innovations take more than great ideas. When our partners bring a new concept to us, we embark on a strategic process to take that idea from its infancy to market. The success of our end-to-end design and manufacturing process is a product of the exceptional expertise we have across every stage of the product life-cycle.

We approach product development with an entrepreneurial mindset and support our partners with the technical expertise and commercial acumen required.

When innovation and commercial acumen combine

- Actualise innovation

- Achieve faster times to market

- Save on development costs

- Expand into new markets

- Capture market share

What can Memjet D+M do for you?

Are you looking for a value-add partner to provide full support throughout the innovation journey? We can help.

Memjet is the global leader in providing digital inkjet technology that enables beautiful precision, simplicity and affordability.

Leveraging this advanced manufacturing capability for its partners, Memjet D+M is shaping the future of innovation with ingenuity, precision and value.